With low gravimetric density, low potential and high theoretical specific capacity, lithium batteries have been ideal candidates for anode material for decades. It not only has potential applications in medical implant devices and portable stuffs, but also in electric vehicles and aerospace industry. However, the truth is lithium batteries suffer from deformation when charging, which leads to serious safety hazard. For a long time, this technical problem has always restricted the development of the entire industry. To stabilize the performance of rechargeable batteries, mountains of works has been done, but the harvest is still infertile. It’s time to jump out of the box. A recent study jointly conducted by Dr. LU Leilei, Pro. YAO Hongbin and Pro. YU Shuhong inhibited the growth of dendritic and mossy lithium remarkably, with a rational design of free-standing Cu nanowire (CuNW) network. This study was published online in Nano Letters(http://pubs.acs.org/doi/abs/10.1021/acs.nanolett.6b01581) as the “Most Read Articles”.

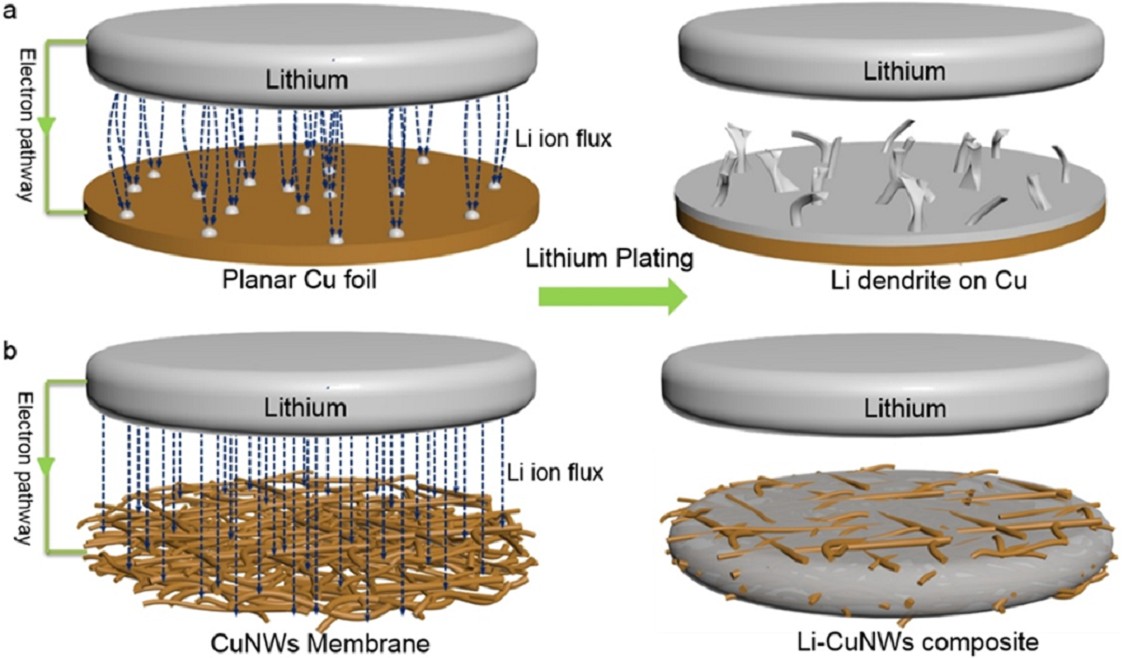

Due to the limit of the craft, the surface of current collector of electrodes can’t be absolutely smooth, which result in heterogeneous electrons distribution and thus asymmetrical deposition of lithium mental. Lithium atoms incline to accumulate in high-electron-density areas and form sharp spines called lithium dendrites. These products can pierce through the separator and trigger internal short circuits. To avoid this dilemma, there are two sorts of strategies. First of all, you can eliminate the origins of lithium dendrites from the very beginning. As a result, scientists developed lithium ion battery. It used graphite to absorb the lithium, prohibiting the participation of lithium mental. You can imagine how limited this kind of combination. On the other hand, you can also choose to hinder the growth of spears. The traditional approach is to consolidate the solid-electrolyte interface (SEI). However, the nature of dendrites generation still exists. Now that trend of dendrites formation is hard to reverse, so why not just restrict them into finite space? It is the key point of the study to introduce a three-dimensional (3D) nanostructure as a current collection. The network not only disperses the direction of spears, forcing them to merge together. It also homogenizes the distribution of electrons and reduces the factors to generate dendrites.

Illustration of Li ion flux distribution and Li-metal plating models on different current collectors

Assembly of nanomaterials has received wide attentions in various fields. The functions of the networks derive from the 3D structure. So, there are no rigid requirements for nanomaterial itself. The diameter and length of Cu nanowires in certain range bring no influence on collections. The craft of assembly is also convenient and suitable for industrial scale-up. Researchers fabricated the free-standing CuNW networks through facile solvent evaporation. Then thermal activation treatment removes oxide layer and fuses the wires together, endowing the film with low resistance as well as mechanical strength.

Except for economical Cu nanowire, silver nanowire, another common material for electronic application, is also scaled up in YU’s lab. For their unique optical property, silver NWs are used in transparent conducting films, like touch screen.

As Pro.YU said: “Era for simply synthesizing nanomaterials is past. It’s time to turn materials-oriented research to function-oriented one.” Bricks and tiles are already, what can we get from the hands of artists? The pure theory is charming, but for practical subjects like the materials science, only application can bring vitality for her, just as Dr. LU did.

The research was supported by the National Natural Science Foundation of China, the Foundation for Innovative Research Groups of the National Natural Science Foundation of China, the National Basic Research Program of China, and the Users with Excellence and Scientific Research Grant of Hefei Science Center of CAS.

(YAN Beibei, USTC News Center, HFNL, School of Chemistry and Materials Science)